T: +44 (0)1257 795761

Make Enquiry about The Overmix - Introduction

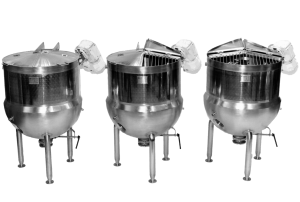

The Overmix - Introduction

A self-contained mixing and cooking unit which has been designed for the processing of sensitive products.

The Overmix has been designed to ensure that whilst the agitation is gentle enough to prevent "disintegration", it is strong enough to mix in additives and give an even result throughout the product.

The anchor agitator is fitted with scrapers which are fitted around the circumference, so that on each full revolution, the heated surface of the vessel is scraped to prevent any materials 'cooking on'. A variable speed agitator can be used, so that a variety of products may be processed in the same vessel, and, if necessary, more vigorous agitation can be obtained.

The unit is designed for easy cleaning, being entirely constructed from stainless steel including the legs, insulation skin and all mounting points for the gearbox and motors. The scrapers are manufactured from hard wearing Nylon 66 or P.T.F.E. and are fully floating. If required, CIP fittings may be provided.

MAIN FEATURES

.Full access from top of vessel for cleaning.

.Hygienic design and construction with no seals or bearing in contact with the product.

.With scraped wall agitation designed to lift and fold delicate products without damage or breakdown.

.Agitator mixes uniformly products like fruit, meat, stews, sauces, pie fillings, rice, vegetables and many other products.

.Whole of the heated surface scraped for efficient heat transfer without any burn-on.

.Many optional features designed to suit your requirements.

.Test units available to guarantee successful products.

OPTIONAL FEATURES

.Agitation - variable speed 5 to 25 RPM.

.Lids - conical, hinged or counterbalanced or pneumatically operated.

.Product temperature indication by PT 100 with analogue display 0-200 degree C.

.Jacket insulated - with mineral wool mat and fully clad in Stainless Steel. (Crevice Free)

.Outlet - can be made up to 150mm (6").

.Load cells and Stainless Steel shrouds.

.Additional Agitation by twin butterfly blades mounted on anchor drive shaft adjustable to vary turbulence.

.Top mounted Multi High Shear Mixer, HP matched to suit vessel size and type of product.

.Bottom Entry High Shear Dual Speed Mixer, Homogeniser.

.Bottom Outlet Falling Stem Flush Valve.